Sadly the engine went bad within the first 100 miles of our ownership. A valve seat came loose, causing the valve not to close fully and the valve struck the piston. Ouch. See the crack propagating from the intake. That is not going to get fixed. Time for different heads.

So, did a full top end rebuild. Full story is in the Blog Section, but here are a few photos.

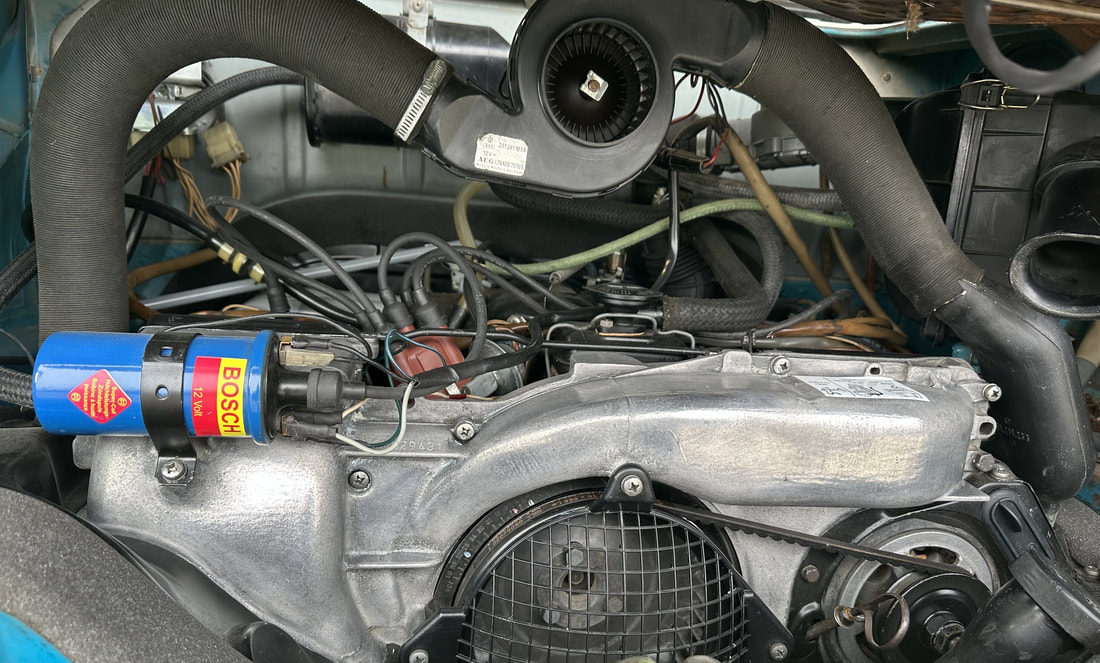

Started with one big filthy mess....

Started with one big filthy mess....

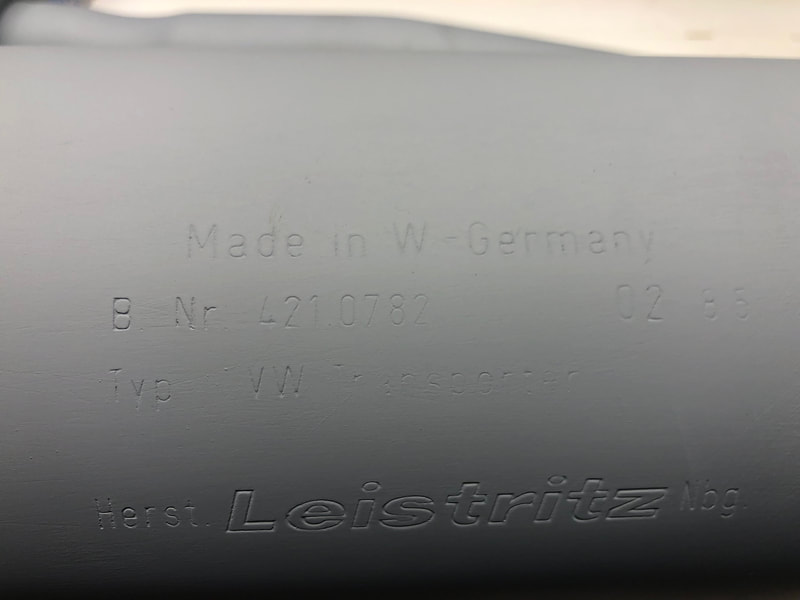

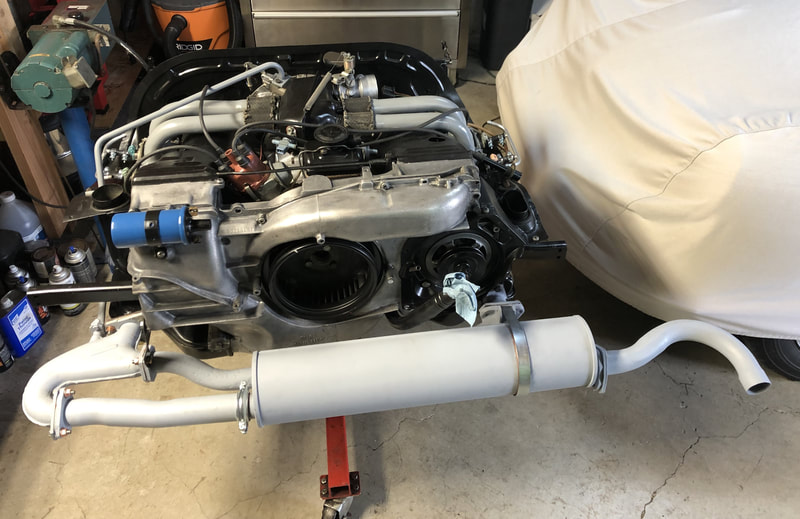

Spent countless days cleaning and painting parts plus sourcing gaskets and waiting for the "new" heads to be machined to perfection. The heads are used VW originals, re-machined with new guides and valves by the famous Northwest Connecting Rods. No welding was needed on the replacement heads. The heads that were in the bus were unusable due to cracks, so they were tossed out! The muffler is NOS!

As described more fully in the Restoration/Blog Section, I sourced an excellent replacement piston. I then balanced all 4 pistons using a very accurate old-school scale. I also checked volume on the heads. You can see the plastic piece with the hold in the center in the photos below. The volumes were identical at 53 cc's and the dish in the piston was 14 cc's, giving a total of 67 cc volume. The engine was still stock stroke and bore (94mm), and after measuring deck height I chose to get the gasket/shims to give me a compression ratio of 8.0

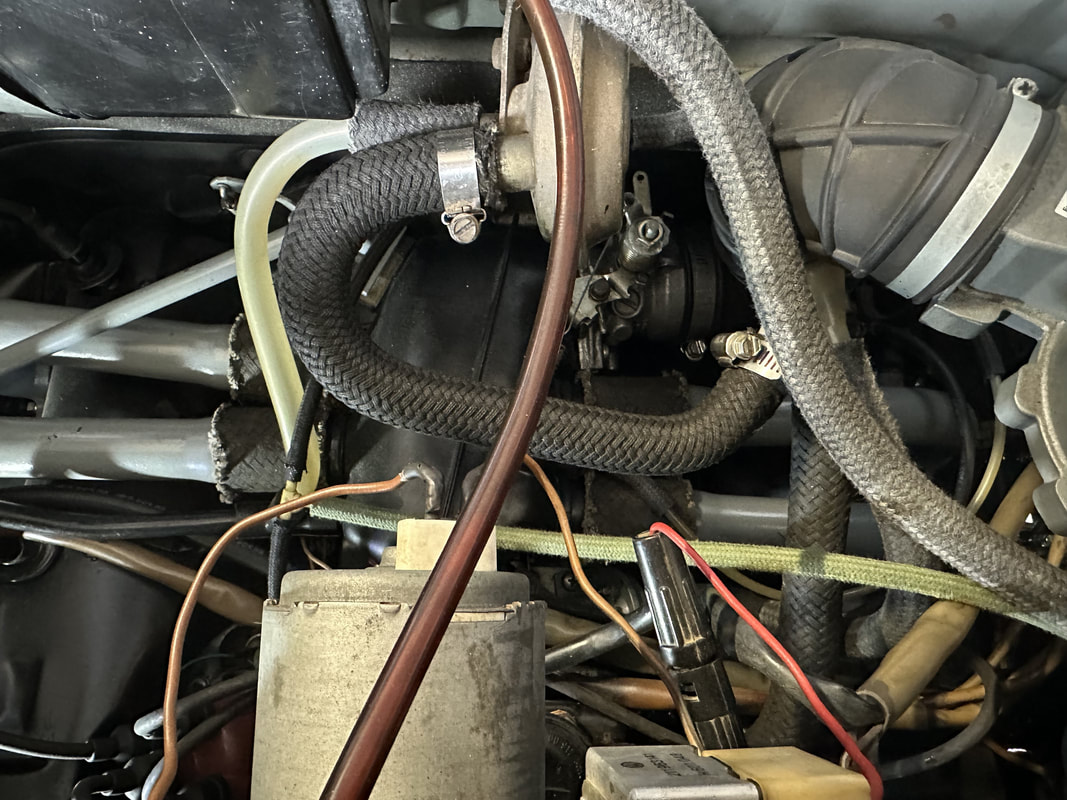

Took me a while to source good condition original braided cloth hoses.

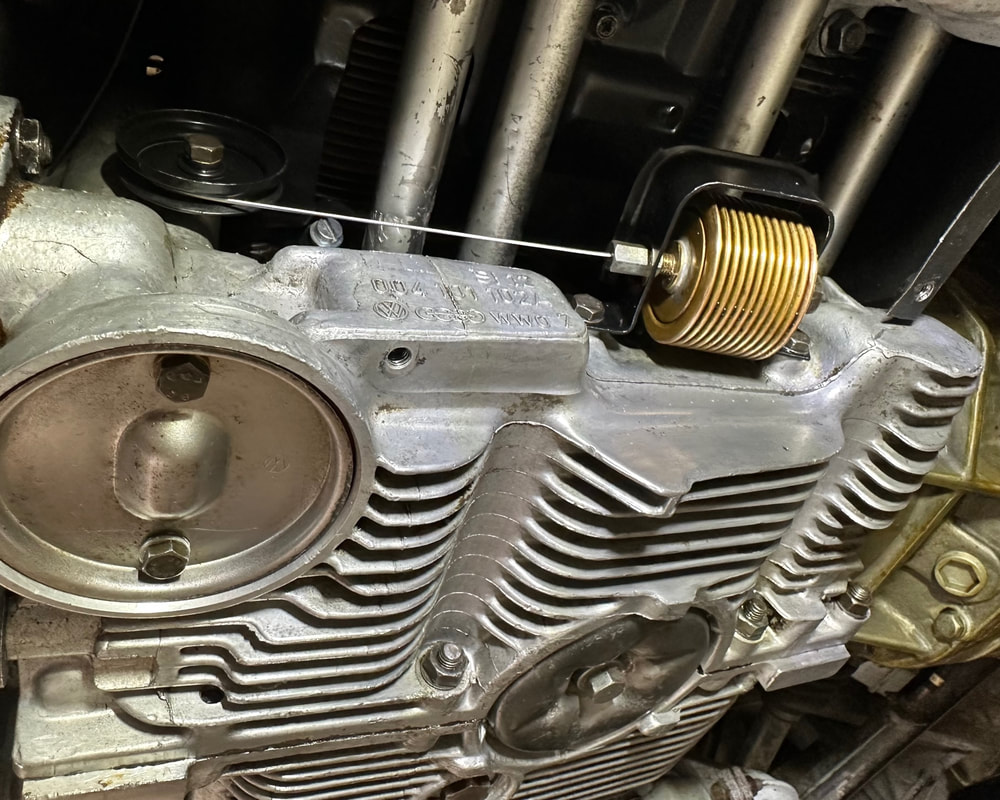

The bellows for the heater had gone bad, and the pully for the actuating cable was broken. Replaced the bellows with a new one and bought a used metal pulley. Shown below.

Engine is running well now. The blower/fan for the heater you see in the photo below also had to be reworked. The bearings were shot.

Engine starts easily every time, has good power, and idles rock solid at 950 RPM.

transmission

The transmission was filthy. Gave it a good cleaning and coated it with a vintage appearance coating. Also changed out the clutch cable and bowden tube. Changed the oil. Shifts great!