|

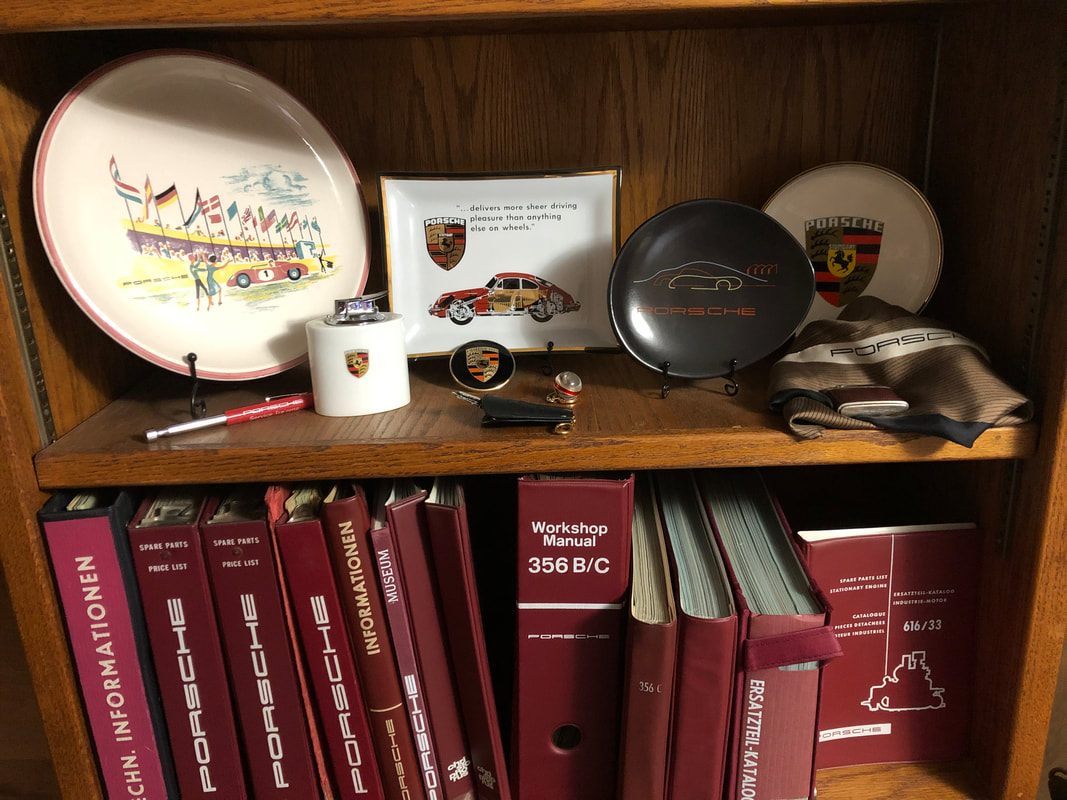

I have a modest collection of PORSCHE automobilia. It's a fun hobby that I enjoy. Today I added a "Flip File" of an incredible collection that was auctioned off a while ago. The collection takes up 169 pages!

To view this amazing collection go to the Misc Section of my website. It is at the bottom of the page. MAKE sure to click on the FULL Screen icon [ ] in the bottom right of the tray. Enjoy!

0 Comments

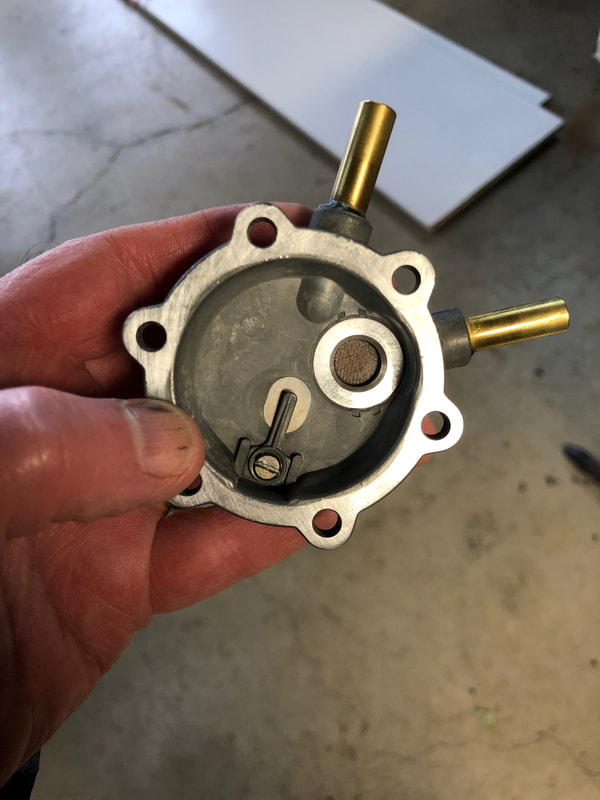

I always strive to do a complete and through job when working on Miss April, but on occasion a component will require me to revisit the restoration of the part. This is definitely the case with my fuel pump. The Saga- About 4 years ago was the first time I opened it up, and it looked great in inside. This was really just an inspection to see if any junk had made it from the fuel tank through the fuel selector valve and then gotten caught by the little screen in the pump. I had completely restored the fuel tank and also completely restored the fuel selector valve, so opening it up was just for inspection and cleaning. Car ran great. Phase Two- The pump developed a small leak at the brass inlet tube on the upper half of the pump. I was able to remove the pump and make a good repair using green wicking Lock-tite. Once reinstalled, the leak was gone and Miss April ran great just like before this repair. We put on a few hundred miles, some of it very spirited driving at the West Coast Holiday (80 mph). Phase Three- Car continued to run very well, rowing through all gears and pulling strong. However,,,, If I left the car at high rev's, around 4k, and held it there for a long time, eventually the car would sputter just a little. If I backed off, the car would run great again. I could take the rev's all the way up as high as I dare, and it would run fine. It only sputtered a little if I held the rev's up for a long time. Seemed the float level was going down and finally one carb would stumble because of low level. Having checked the float levels several times, it seemed fuel supply was the issue. On this third attempt, I wanted to do everything possible that could be done to the fuel pump, but first I wanted to diagnose if it had a problem. One problem to check out was the "check valve" on the outlet of the pump. This check valve keeps flow from going backwards when the diaphragm is going down. It prevents backflow, which if there is any backflow, the net result is both lower pressure and lower flow to the carbs. I decided to take the pump apart, clean thoroughly, and then submerge the pump in water, blowing back towards the pump while connected to the outlet pipe. Below is the result of this first test- The above shows the check valve was not sealing. The check valve is difficult to remove, requiring drilling to remove the 4 small spots where the valve was "staked" into place. I decided to avoid this and seriously cleaned everything first. I folded over some very light sandpaper and gently went around the interface of the disk to seat. I followed that with lots of simple green spray, and then a soak in mineral spirits. Lastly I used compressed air from both directions. Then it was time to test again. Same test... Yahoo! Tight shutoff! Next step was to make sure the mating flange surfaces of the body were flat. I used a fine flat faced file to get close, then finished the surfaces by using wet or dry sandpaper on a flat surface. The result was much better. These flanges get bent from people tightening down the screws too much, and this repair is something I would recommend to anyone who has their pump out for repair. I had extra springs from other repairs I have done over the years, and there is some variation in the length of the large pump spring. I went ahead and used the old springs Proceeding on to assembly, one thing that is somewhat tricky is compressing the springs so that the "C" clip can be installed on the end of the push rod. Holding it all together is difficult by hand, and compressing it in a vice covers up the end where the clip needs to go. Rummaging through my junk drawer, I found the perfect thing-- it is from a light fixture where you connect a room light to a junction box. The hole was just the right size to fit over the spring end cap but let the shaft push through. Instead of a vice, I used zip-ties to hold it low enough to install the C clip. Last step is to make sure the diaphragm is flat when tightening down the screws around the flange of the body. I cut off the zip ties and then used two more to adjust the height of the diaphragm to exactly where I wanted it. Then I installed the upper body while keeping the diaphragm flat. Done! Should be good for miles and miles of pumping fresh fuel to the carbs! After installing a rebuilt pump, it is a good idea to re-check float levels. Here is a shot of the level in my passenger carb lining up perfectly at Z3 level on my gauge. Right where it should be. Also, if I take the car up to 4k RPM and hold it there while watching the level, it stays right on the line. After all the above, a great test drive. Here is a shot taken in THIRD gear. Love it!

Ashes to ashes, but not in this ashtray! The drawing/sketch on this ashtray is my absolute favorite one from the factory! It showed up on some early driver award plaques, salesman binders, Liebe Zu Ihm and other places. Finally PORSCHE commissioned Ulmer Keramic to make this ashtray, along with many other marketing pieces. These are expensive, and this one is pristine. I just think it is wonderful and had to share a photo of it. In the photo of the bookshelf, the large plate on the left is also Ulmer Keramic. You can do a search of my website and find out more about that plate and some matching placemats I have. So happy to finally have tracked down one in this condition and now have it on the shelf! Here is a photo of it with the PORSCHE INFORMATIONEN binder that you see on my shelf. I describe the image as a 356 with wind going over the top, and underneath the 356 is a 550 body. In the background is the roofline of the factory.

These fun old sports cars are supposed to make us feel happy. They are, after all, a hobby. Well, yesterday I felt cranky about my 356.

ALL 660 COLD CRANKING AMPS of crankiness! I bought and installed another new battery for Miss April, replacing one that was only 9 months old. I did this because last Summer I did a bunch of research and web browsing to find out the closest size modern battery to what was original to the car. I believed at the time it should be a 19L battery, which I managed to track down. The battery has 440 CCA (cold cranking amps). Although it would start the car, it was just too sluggish for me. If turning the engine over and deliberately not starting the car so that I could circulate the oil, the revolutions would slow down and just sound tired. Realizing I have not yet installed a starter relay or replaced the starter bushing in the trans, I still was unhappy with the battery. I will get a relay and replace the starter bushing soon, but I want a strong battery I can trust. The solution I chose was to move up to a Group 1 size battery. Fits nicely in the battery area of the T6 battery box, and after removing the modern stickers and attaching a Varta plaque to make it look a bit more like a battery of the period, I'm happy. It's much stronger (50%). I could have chosen an Optima battery (this car came with one) and put it in a plastic box that is made to house them and gotten even better CCA, but I did not want to alter the original plastic battery cover or make any other changes. Photos of my nice strong new battery below. Quite cranky! |

restoration & blog Archives

July 2023

|